Factors Affecting the Efficiency of Bag Filter Systems

Bag filter systems are widely used in industrial facilities to control dust and particulate emissions. However, the efficiency of these systems varies depending on several factors. This article outlines the key elements that influence the performance of bag filter systems.

- Selection of Filtration Material and Bag Type

- Material Durability: The type of filter bag material (polyester, Nomex, PTFE, etc.) has a significant impact on filtration efficiency.

- Temperature Resistance: Filter fabrics that can withstand high temperatures improve efficiency in systems operating under high heat.

- Abrasive Properties of Dust: Abrasive dust can wear down filter fabrics faster, negatively affecting efficiency.

- Filtration Grade: Selecting a filter grade that matches application requirements is critical for system performance.

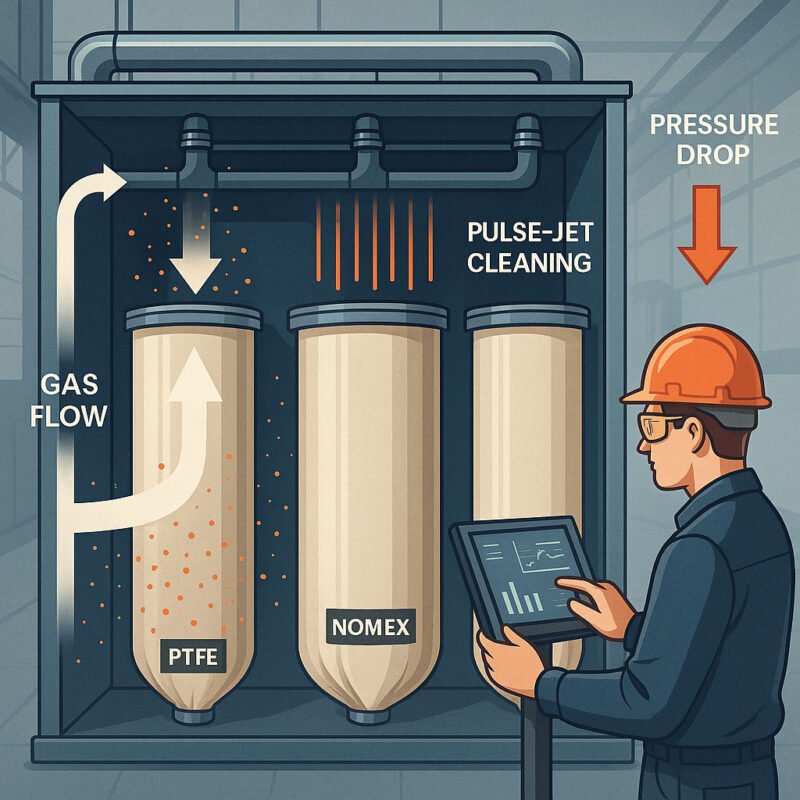

- Air-to-Cloth Ratio and Gas Flow

- Air-to-Cloth Ratio (A/C Ratio): The ratio of airflow to the surface area of the filter fabric directly affects efficiency. High airflow may clog the filters faster, reducing performance.

- Gas Flow Uniformity: Uneven distribution of gas across the filtration area can lead to overloading in certain zones, decreasing overall efficiency.

- Cleaning System and Its Efficiency

- Cleaning Method: The efficiency of pulse jet or mechanical cleaning systems is directly related to how effectively they remove particles from the bag surface.

- Cleaning Intervals: Ideal cleaning intervals prevent clogging and ensure continuous high performance.

- Pressure Drop: Pressure differential across the filter bag is another key factor. A high pressure drop indicates reduced filter efficiency.

- Size and Design of the Filter Bag

- Size and Geometric Design: Proper bag dimensions and design ensure even gas distribution across the fabric, enhancing efficiency and preventing blockages.

- Seams and Connection Methods: The quality of seams and connections affects filtration performance. Poor connections may cause air leaks.

- Operating Conditions and Environmental Factors

- Humidity and Temperature: High humidity increases dust adhesion to the fabric, reducing performance. Also, low temperatures can affect the efficiency of certain filter fabrics.

- Dust Load and Composition: High dust concentration can lead to rapid clogging of the bags, decreasing filtration efficiency.

- Filtag’s Role in Bag Filter Systems

- High-Efficiency Filter Fabrics: Filtag offers high-performance filter bags tailored to various applications to improve efficiency.

- Durable Material Options: Filtag provides long-lasting filtration solutions with materials resistant to abrasive and high-temperature environments.

- Easy Maintenance and Cleaning Design: Filtag’s filter designs simplify maintenance processes and support long-term efficient operation.

Conclusion

The efficiency of bag filter systems depends on correct material selection, proper design, suitable operating conditions, and effective cleaning mechanisms. Filtag solutions are developed with these factors in mind to ensure maximum performance.